Fiber Bragg Grating revolutionising railway safety

Not much time ago we’ve been speaking about optical technology in railway systems that will improve performance and reduce costs (https://www.railwaysignalling.eu/railway-optical-technology); so let’s speak now in a little more detail about Fiber Bragg grating (FBG) technology that would transform railway transportation safety.

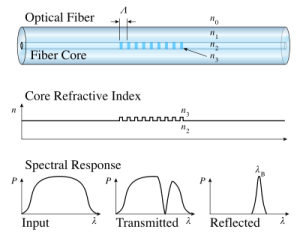

A Fiber Bragg Grating is a type of distributed Bragg reflector constructed in a short segment of optical fiber that reflects particular wavelengths of light and transmits all others. This is achieved by creating a periodic variation in the refractive index of the fiber core, which generates a wavelength specific dielectric mirror. A Fiber Bragg Grating can therefore be used as an inline optical filter to block certain wavelengths, or as a wavelength-specific reflector.

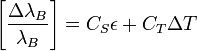

The reflected wavelength, called Bragg wavelength, depends strongly by physics characteristics of the fiber, but it is also sensitive to temperature and strains. This means that Fiber Bragg Grating can be used as sensing elements in optical fiber sensors. In a FBG sensor, the measurand causes a shift in the Bragg wavelength. The relative shift in the Bragg wavelength due to an applied strain and a change in temperature is approximately given by the ratio:

where C_S and C_T are the coefficient of strain and the coefficient of temperature respectively.

As FBG sensors are suitable for extremely harsh environments, they can be embedded along the tracks or within mechanical compartments of carriages. In the event of a defect, such as excessive vibrations, or the weight of the train becoming off-kilter, the reflection spectra is altered.

At the Hong Kong Polytechnic University further improvements are under study and they will make possible to measure the real-time weight of trains in operation. “Weight measurement is obviously really important,” says Hwayaw Tam, chair professor of photonics, “If an operator is able to know the weight of the axle – either on the right or left side – there is potential, using that information, to prevent derailment. It’s something we are really looking into at the moment.”. Furthermore it seems that this kind of sensor “Not only is it perfect for enhancing safety on railway systems, but it is extremely energy and cost efficient [it purportedly saves the rail company in the region of $250,000 each year in maintenance costs alone]. It is roughly around a third of the price of other warning systems currently on the market.”

Let’s keep watching on this!

Sources:

http://www.railway-technology.com/

Did you like this post? Would you like to be informed about the last railway signalling technical and commercial news? Join us on LinkedIn and stay updated!

railwaysignalling.eu | walk the rail talk